|

|

|

|

|

"Simple Manual Abrasion---The stone abraded being held in the hand and rubbed on another stone or abraded by another stone held in the hand". W.H. Holmes, 1919.

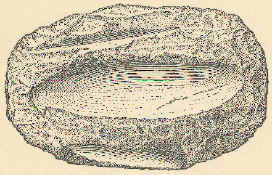

AXE GRINDING STONE

Stone axes have been an important component of primitive Stone Age tool kits for many thousands of

years. Grooved axes extend back in time to the Archaic period in North

America. Grooved and ungrooved stone axes have been found on aboriginal sites

around the world. Modern experiments using stone axes to cut down trees

have shown that they work very well for that purpose. An experiment carried

out in Denmark in 1954 concluded that one man could clear about 5 acres (2

hectares) in one week. Oak trees greater than 13 3/4 inches (35cm) in diameter

were not cut down but girdled and left to die. |

|

|

The material of choice for smoothing and sharpening the surfaces of stone axes is sandstone. By using water as a lubricant which helps to create a "grinding past" the cutting bit of an axe can be sharpened to a pretty fine edge. Sometimes when sandstone is not available, materials like some forms of limestone have been used to sharpen stone axes. |

|

|

Sandstone was also used to shape, smooth and sharpen such things as bone knives, awls, needles and items made of antler, shell and wood. |

|

|

"REFERENCES"

1912,

"Handbook of American Indians North of Mexico", by Fredrick Webb

Hodge, pp. 6, 7. |

|

| CONTINUE ON TO PAGE TWO | |