|

|

|

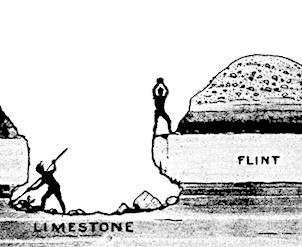

Holmes describes the ancient process of mining flint at Flint Ridge from an excavation of one pit and observations of others. He explains that first a pit was dug to the surface of the flint stratum below. But then he mistakenly explains that fire and water were used in alteration to shatter the stone until the excavation reaches a depth that allowed them to work with sufficient room. Other archaeological excavations of pits have not shown any evidence of the use of fire to mine through the flint and limestone stratum. Roy also has not seen any obvious use of fire in any of his excavations, as explained by Holmes. Ancient miners were most probably extracting the flint with the use of pry bars and hammerstones. |

|

|

|

|

After the raw pieces of flint were removed from the quarry pits, they were carried to nearby workshops. These workshop sites range in size from fairly small to five or ten acres. These sites can be identified by a thick surface layer of flint percussion flakes. First stage preform production was carried out on these sites. Holmes estimated that 90% of the stone brought to these workshop sites ended up as waste flakes and flawed stone that was rejected. The much smaller lighter and easier to transport preforms were then traded to more distant locations where finished tools, such as projectile points, knives, scrapers, perforators and other specialized tools, were made. |

|

|

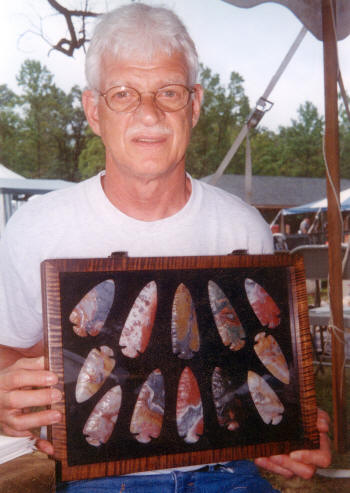

Roy Miller mines flint on his own land. He says he knows when he's near a good flint outcrop when he begins to find signs of ancient mining. The evidence is in the form of hammerstones left behind many thousands of years ago. Holmes reports that one hammerstone they found in an excavated pit was extraordinarily large, It-- "weighed nearly or quite a hundred pounds." Roy digs the site with a backhoe and by hand. |

|

|

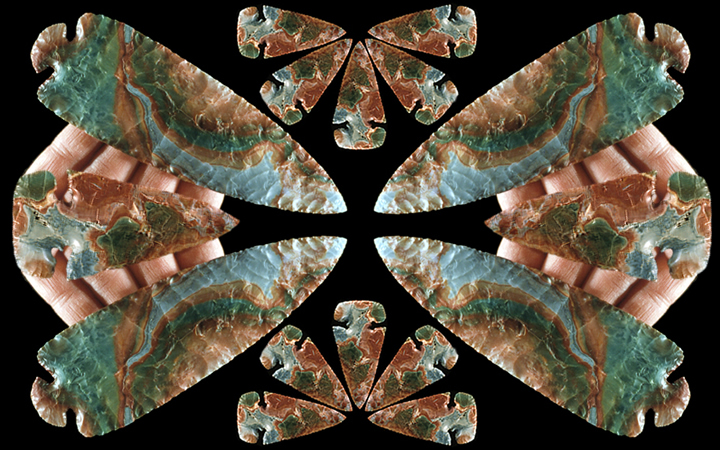

Roy makes his points out of heat treated Flint Ridge flint. The raw flint, as it come out of the ground, does not have the extreme colors we see in the finished points. Raw flint is usually gray or blue gray with additional varying bands of yellow and red. But raw flint does not have the intense colors until the preforms are heated. Roy heats his flint in an electric kiln. Heat treating is a long process that takes three to four days from the time it's placed in the oven. The kiln is programmed to slowly raise the temperature 25 degrees per hour until it reaches 500 to 550 degrees for no more than five hours. The kiln is then turned off and allowed to slowly cool before the flint preforms are removed. Roy says that if you control the temperatures precisely you can bring out more of the yellow colors with a slightly lower temperature and more of the reds with a slightly higher temperature. Heat treating also changes the fracturing qualities of the stone, usually making it easier to flake. |

|

|

|

|

Site manager Jim Kingery, at Flint Ridge State Memorial has been quoted as saying about Roy Miller that "He is a master----Everybody recognizes him as a master." Roy has certainly earned the accolades. His points are a legacy that will last long into the future. It's obvious they were made by someone who studied the ancient craft and mastered it exceptionally well. |

|

|

"REFERENCES"

1892, Moorehead, Warren K., "Primitive Man In Ohio," p. 31. |

|