|

CLICK ON PICTURE

FOR A LARGE TRIPLE IMAGE

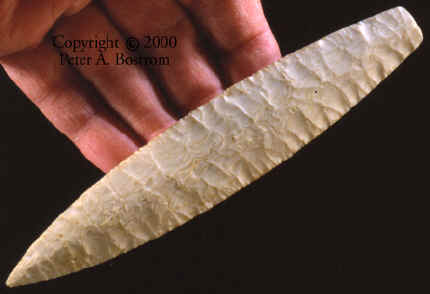

CLOVIS POINT BY TIM DILLARD

DONNIE McKINNIS

COLLECTION

This Clovis point is made of Kaolin chert from southern Illinois. It's

made the same as a Clovis hunter would have made his spear point 14,000

years ago. This point measures 3 7/8 inches long.

CLICK ON

PICTURE FOR A LARGE TRIPLE IMAGE!

DALTON POINT BY

TIM DILLARD

DONNIE

McKINNIS COLLECTION

Tim is known as one of the best maker of Dalton points. This example shows

very expertly done parallel flaking and good over all form. As skilled as

he is at making Dalton points he does admit though that he doesn't know

how the large "hollow ground" flaked Daltons were made. No one

has yet been able to duplicate them. This example is made of Burlington

chert and measures 5 3/4 inches long.

CLICK ON

PICTURE FOR A LARGE TRIPLE IMAGE!

CUMBERLAND POINT BY TIM DILLARD

DONNIE

McKINNIS COLLECTION

This Cumberland point is made of Cobden chert and measures 5 inches long.

The channel flake is very smooth and it's fluted to the tip on both sides.

CLICK ON PICTURE FOR A LARGE

TRIPLE IMAGE

FULTON TURKEY TAIL BY TIM DILLARD

DONNIE McKINNIS COLLECTION

This Fulton Turkey Tail is made of Indiana Hornstone and measures 5 15/16

inches long. Points of this style have been found in caches and date to

the late Archaic period.

CLICK ON PICTURE FOR

A LARGE TRIPLE IMAGE

AGATE BASIN POINT BY TIM DILLARD

DONNIE McKINNIS

COLLECTION

This Agate Basin point is very well made and the flaking is precisely the

way ancient ones were made. This one is made of white Burlington chert and

measures 5 3/4 inches long.

CLICK ON PICTURE FOR

LARGE PICTURE OF SEVERAL LARGE BLADES (bifaces)

LARGE MISSISSIPPIAN SWORD BY TIM DILLARD

DONNIE McKINNIS COLLECTION

This large Mississippian culture style "sword" illustrates very

well the skill level Tim has attained from 21 years of flaking stone. This

blade (biface) is made of Mill Creek chert, a material more difficult to

knap than many of the more common stone like Burlington chert. This

example measures 11 inches long. Click on the picture to see blades up to

15 inches long.

CLICK ON

PICTURE FOR A TRIPLE IMAGE

HARDIN-BARBED

POINT BY TIM DILLARD

DONNIE

McKINNIS COLLECTION

This Hardin Barbed point is made of white Burlington chert. It's another

fine example of Tim's ability to duplicate Early Archaic point types. This

point measures 5 3/4 inches long.

CLICK ON PICTURE FOR

A TRIPLE IMAGE

ROSS POINT BY

TIM DILLARD

DONNIE

McKINNIS COLLECTION

This Hopewell Ross styled point is made of semi-translucent Knife River

flint from North Dakota. It measures 6 1/4 inches long.

CLICK ON PICTURES

FOR GROUP OF DICKSON'S & TRIPLE VIEW OF ONE TO RIGHT

DICKSON POINT BY TIM DILLARD

DONNIE McKINNIS COLLECTION

This long and thin Dickson point on the left was made from heat treated

Burlington chert. Tim is able to make Dickson points as thin as he wants.

This point measures 8 1/8 inches long. The one on the right is beveled. It

measures slightly over 6 1/2 inches long.

CLICK ON PICTURE FOR

A MUCH LARGER PICTURE

TURKEY TAIL POINTS BY TIM DILLARD

DONNIE McKINNIS

COLLECTION

These Turkey Tail points were all made from Indiana Hornstone. The

majority of all ancient Turkey Tail points were made of this material. The

longest point is this group measures 6 1/4 inches long.

|